My Experience

Kinze Manufacturing gave me the opportunity the summer of 2019 through the fall of 2019 to work as a Test Electronics & Control Engineer Co-op. During this time, I worked with the Test, Design Engineering, Continuous Improvement, Quality Control, and Electronic Engineering departments. With this work, I met and learned from many people how large companies work from many points of view.

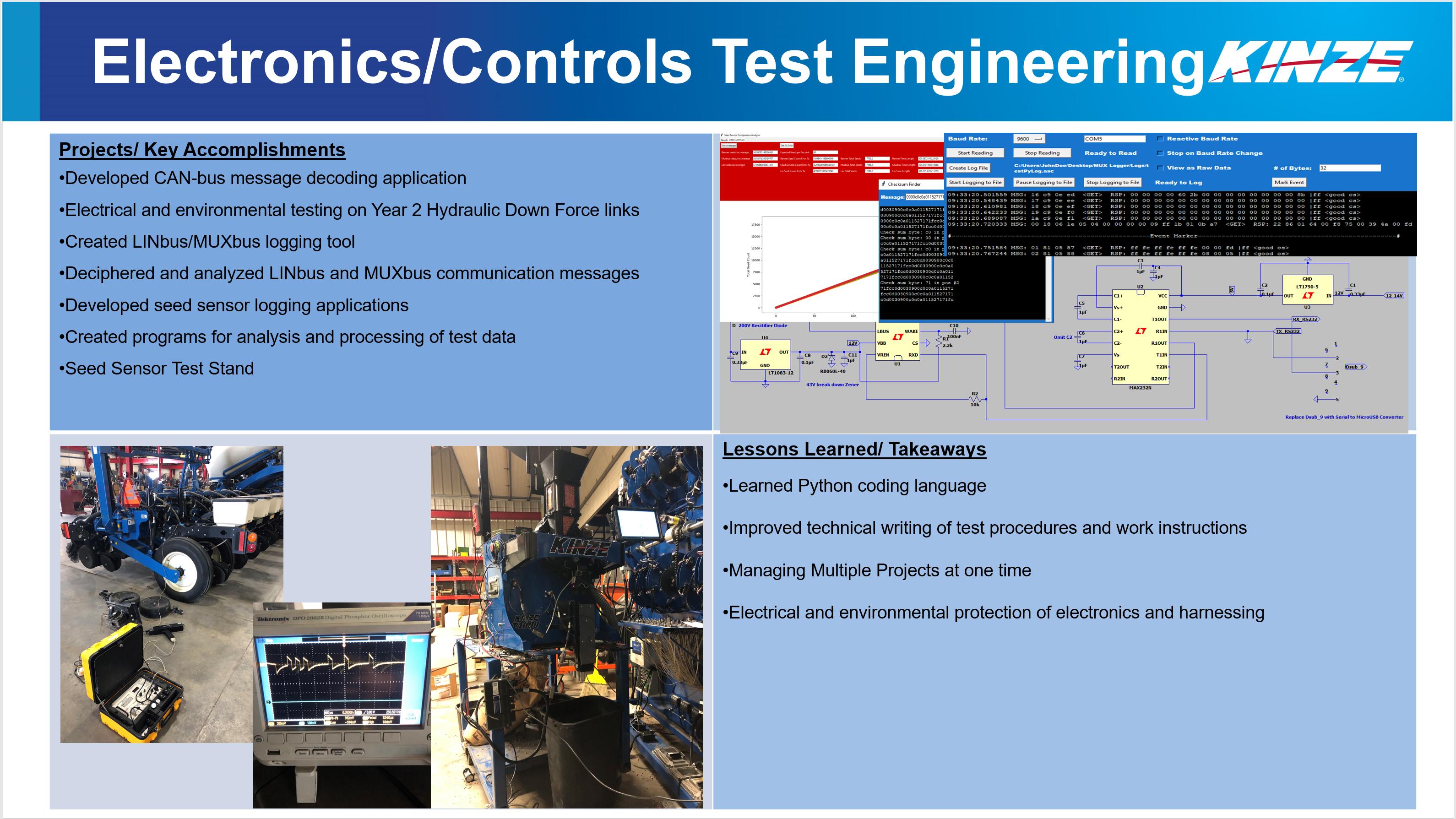

The first task I was assigned at Kinze was to create an application that could take CAN control system messages and parse them into human readable messages. The hardest part of this project was gathering all the different CAN messages from other engineers and companies. The next challenge was the design of the application. Another Co-op and I teamed together and decided that leveraging python would probably be the best for this application since it was a widely used coding language in the company. So, we both learned Python and got a fully working application in 3 weeks and finalized it in 7 weeks. However, this was not the only project I worked on at the time; I also was assigned to help find a software bug on a planter's control system. I spent days looking for signs of a trigger for the software bug, but kept coming up short on reproducing the issue. Therefore, I decided to develop a control system message logger for the planter to get all the messages from the planter's control system and give engineers the ability to read through the communication data to help pinpoint the bugs. I created a prototype that could read the serial data off the control system. I later created an active GUI to make the data easy to read and track because the messages are not easily readable without proper formatting. I then had to parse all the data into human readable code, but the data was proprietary. To make the proprietary data readable, I worked with another company on finalizing the application and device. During this work I learned about control system protocols and capabilities.

With a new device that could read a legacy proprietary control system, my next project was to use the device to compare new seed sensors with the legacy seed sensors that had the proprietary messaging. Other engineers and I created another application that could read both the seed sensors in real time using the messaging and external optical sensors. We were able to collect a lot of accurate data, but the data was difficult to analyze because looking at hundreds of numbers can be hard to put into perspective. Therefore, for my final project I created an application that could take all the data from the seed tests and create proper graphs based on the given data and would automatically compute any calculation the engineers would need. This application was complicated because of all the different time constraints within the data collection. The data needed to be accurately represented so that it was not to mislead any of the engineers or anyone in the company.

While I worked at Kinze, I also worked on electronic testing of control systems sensors. I performed thorough electrostatic discharge (ESD) tests and other environmental tests with simulation chambers. Any sensors that failed a test would need to be investigated further and I would find and prove issue components from tests. I did a lot of extensive documentation for my work at Kinze. I documented meticulously documented every step of my test procedures and results. I also made comprehensive user manuals for all of the applications and devices I made. These user manuals were two to three dozen pages each with step-by-step guids, trobleshooting, and detailed designs. I think having good documentation for work you've done is extremely important so that other engineers can continue using your projects and possibly improve upon them.

Overall, my experience at Kinze was both eye-opening and rewarding for me. The staff were very professional, and the other co-ops were fun to work with. I learned countless valuable skills from my memtor and other engineers. With the co-op experience I had at Kinze, I learned how to network and collaborate engineers, how to create elaborate and concise technical documentation, and how to take an idea and make it into a working application. Thanks to Kinze, feel considerably more confident about entering the workforce as an engineer after graduation.